Hello everybody.

I’m Atsushi Mabuchi, CEO of my company.

Today, we will show you our company.

I’m grad to meet you.

Our company process the building materials.

We are able to process the board plenty.

For example, milling, cutting, ruminating, painting, edge milling, rapping, pressing, and others.

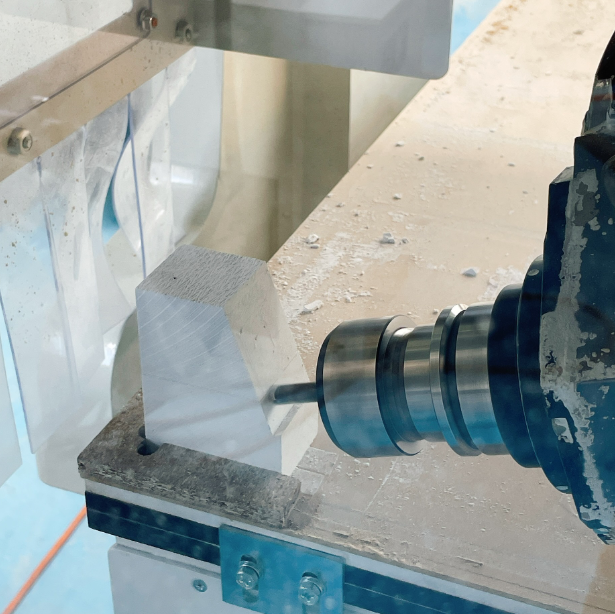

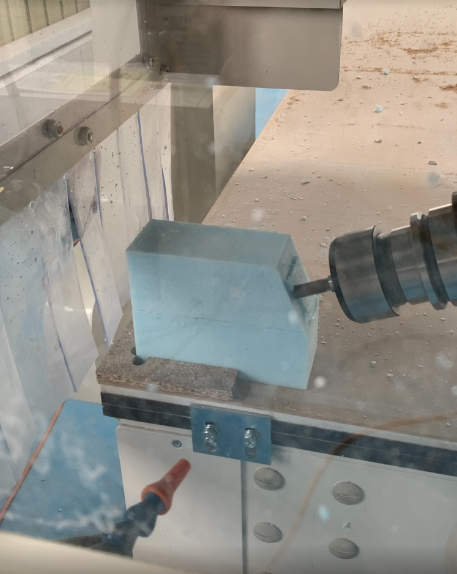

Could you look at the machine?

It’s milling machine.

There are features.

1.

This machine is able to process big materials.

About until 3m and 1.6m.

2.

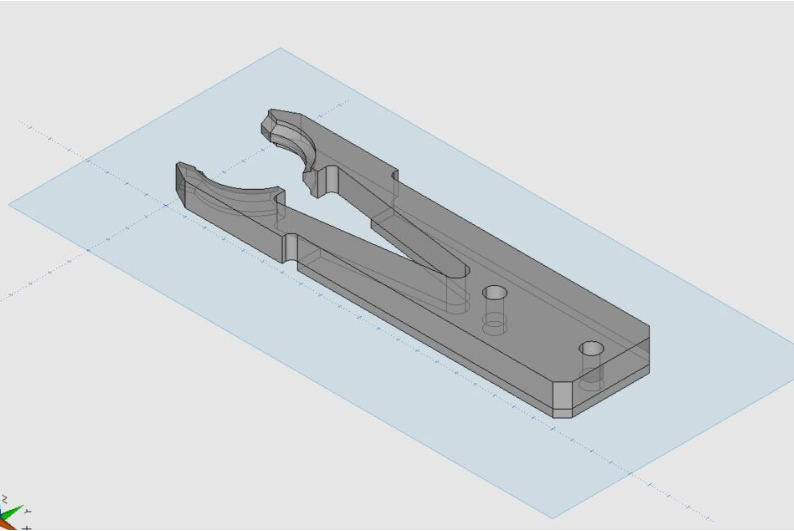

This machine is moved by original CAD data.

This is 5 axis machining.

3.

CAD data is transferred by office network.

So, our machines are absolutely accurate and fast.

By the way, have you ever seen this machine before?

It’s called “panel saw” in japan.

It’s most famous machine in Japan.

It needs to stand the board vertical.

So , it doesn’t have to get the space.

By the way, go to the next.

I will show you the beam saw.

It’s popular especially in Europe.

It’s so big.

Its feature is fast and accuracy.

It’s rigid.

Too rigid.

So, it’s endurance.

We can process the board hardly.

Other feature is light.

It is not machine weight.

Could you look it?

There are many quantity of holes.

This role is air blowing.

The air are able to push up this board.

So, we are able to move the heavy board easily.

By the way, let’s go next.

The machine is called cabinet maker.

It makes the cabinet.

It is able to made a cabinet fast.

It means is not physical milling fast.

This use original CAD data.

So, it makes cabinet freely only 5minutes.

Let’s go to out the factory.

Next, this is number 2 factory.

This factory uses the robot.

Robot anytime need very difficult programs.

It looks like dictionally.

But, our factory uses the our operation system.

so, process engineer use easily.

It operation is very easy.

so

If newcomer take a work at first,

we can use easily.

If you can use the little calculator,

you can use the robot.

Our engineer have to work that we work easily.

So, our engineer is anytime reading book and research, attempt.

Our management philosophy is to worker and customer become happy.

Always laughing is our goal.

by the way, let’s go to the other factory.

The next is painting, ruminating, to paint the foundation.

Its very rarely process department in Japan.

Its machine is called laminater.

Currently, our houses are used the laminated materials. Almost everything.

This machine have a feature, little bit amount and fast.

Almost company is able to process the big amount.

Only big amount.

But our company is able to little bit amount

and fast exchangable.

Let’s next.

Its painting machine is able to paint face side and backside.

Inorganic materials need the to paint the foundation.

Its so smell.

but it must be need.

Let’s go to the next.

Could you see the machine?

This machine is bonding machine.

Bonding is that materials to be integrated by different materials.

This use is changing the thickness.

This use is changing the surface finish.

This use is making the beautiful to surface.

This machine is able to bond the many kind of materials.

For example, plywood, raw wood, face wood, inorganic board, plasterboard, cement board, other.

Finally,

this machine is panel saw.

By the way,

Let’s go to the next.

It’s, my traditional factory.

Its under construction.

It very wide.

So, we are able to process other things.

Please ask me if you have any problems in your company.

We hope to achieve your dream.